Case Study: Wisson's Robot-enabled Cleaning Solutions, Enhancing Safety and Efficiency of Wind Turbine Maintenance

2024-08-22

Background

China's wind power industry is booming. In 2021, grid-connected wind power capacity surpassed 300 gigawatts, leading the world for 12 consecutive years. From 2021 to 2025, wind power generation is expected to grow from 829.45 billion kWh to 997.08 billion kWh, with a steady annual growth rate of 4.7%.

In China's northwest region, the excellent wind conditions have led to the deployment of numerous wind power facilities, making it a significant hub for wind energy development in the country. However, these wind turbines face environmental challenges. Continuous exposure to wind and sand causes the paint on the wind tower surfaces to erode, leading to rust on exposed metal parts. Additionally, long-term use results in lubricating oil and other contaminants seeping onto the tower surface, impacting both the appearance and structural integrity of the towers, and potentially leading to tower collapse in severe cases. To ensure equipment longevity, maintain power generation efficiency, and reduce accident risks, wind power operators or equipment providers in this region often need to inspect and clean the towers regularly.

The client in this case operates a wind farm in northwest China, with over 120 wind turbines. So the routine maintenance workload is substantial, and they face numerous limitations and challenges associated with manual cleaning. Currently, cleaning typically involves personnel climbing the towers, using suspended baskets, or elevating platforms, which requires certified operators and is limited by human resources. The actual cleaning process is labor-intensive, inefficient, and poses significant safety risks. Additionally, manual operations struggle to effectively clean curved and other complex surfaces.

Challenges

High-altitude operations are extremely hazardous, requiring highly skilled and experienced personnel, and always carry safety risks.

The complex environment increases the difficulty of cleaning, with manual cleaning requiring tower climbing or using suspended baskets, leading to high labor intensity and low efficiency, making it challenging to quickly complete maintenance on a large number of units.

Existing conventional or automated cleaning solutions struggle to cover narrow and complex spaces or components like blades, affecting maintenance effectiveness.

Solution

Based on the client's needs for safety, effieincy, and coverage area, the solution utilizes Wisson's Orion AP30-P2 Pliabot® aerial high-pressure cleaning system as the core of the operation. This product is an unmanned cleaning device designed for high-altitude operations, equipped with high-pressure cleaning capabilities and supporting various liquids such as water and cleaning agents. It features real-time rangefinding and seamless integration with the flight system, allowing single-person control of both flight and cleaning. The AP30-P2 can operate at heights of up to 200 meters (656 ft) and has a maximum spray distance of 6 meters (19.6 ft) from the drone to the working surface, providing full coverage cleaning of the wind tower and blades, meeting the client's requirements.

The operations team first assessed the 120 wind turbines in the client's area, identifying 20 for cleaning. The contaminants included dust and light oil stains. The solution provided a professional cleaning agent set for light oil stains and the AP30-P2 system. According to the operational plan, the team conducted cleaning operations at the wind farm, efficiently achieving the expected maintenance results and benefits.

Client Benefits

Replacing Manual Cleaning to Ensure Personnel Safety: Operators only need to remotely control the AP30-P2, eliminating the need for high-altitude operations and ensuring safety.

Significantly Improved Efficiency and Reduced Costs:

Traditionally, a team of five people would take five days to clean a single unit. Now, with the new solution, one person can complete the task remotely in one day, greatly enhancing efficiency.

For this specific client, by using three AP30-P2 systems simultaneously, the team can clean three wind turbines in one day, completing the entire wind farm's cleaning tasks within a week, significantly improving both efficiency and safety.

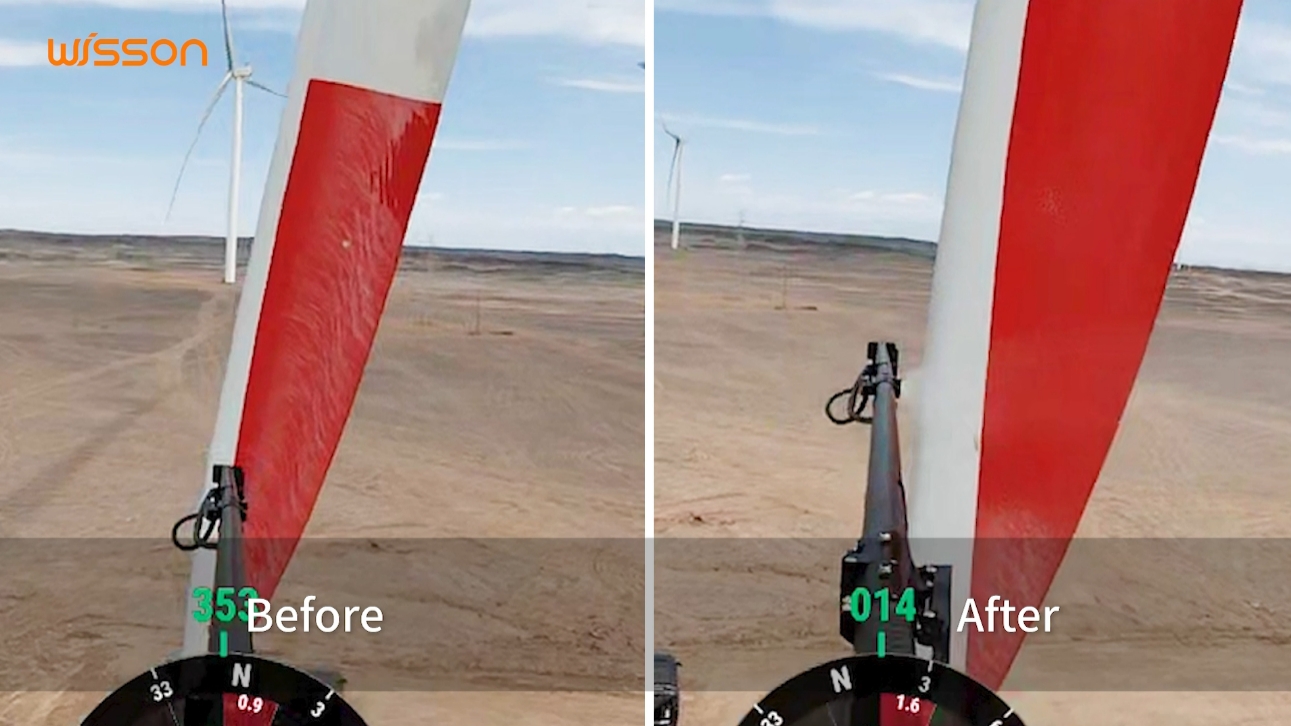

Effective Dust and Oil Stain Removal with Remarkable Cleaning Results: The high-pressure cleaning system, supporting various cleaning agents, effectively handles dust and light oil stains, providing immediate and noticeable results.

Comprehensive Cleaning of Entire Units, Including Difficult-to-Reach Blades: The adjustable nozzles ensures complete coverage of the tower and blades, providing a comprehensive cleaning solution.

Safe and Stable Equipment Operation: The AP30-P2 operates at heights of up to 200 meters (656 ft), with a maximum spray distance of 6 meters (16.9 ft) from the drone to the working surface and real-time rangefinding to ensure optimal and safe spraying distances.

The client fully recognized the efficiency and safety of Wisson's wind power cleaning solution, further enhancing their wind turbine maintenance capabilities with innovative technology and methods, ensuring the long-term stable operation of the wind farm. Meanwhile, the application of the AP30-P2 as the core of the solution offers new ideas and options for future high-altitude cleaning operations, not only for wind turbine but also widely applicable for cleaning photovoltaic panels, insulator strings, buildings, walls, and high towers. This meets the high-efficiency and safety cleaning needs across various industries, providing a convenient, efficient, and stable aerial high-pressure cleaning solution.